Sunday, August 26

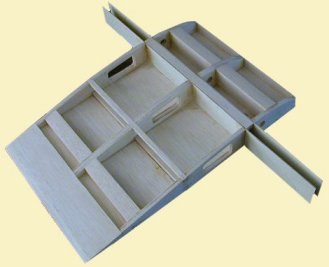

Two weekends away do not lead to rapid aircraft production, but one in Ithaca and the other at the beach do lead to peace of mind! Yet the wing center section was completed even so. This was a complicated piece, well, perhaps not so much complicated as requiring significant care in getting everything aligned and perpendicular or at some particular angle or other.

Two weekends away do not lead to rapid aircraft production, but one in Ithaca and the other at the beach do lead to peace of mind! Yet the wing center section was completed even so. This was a complicated piece, well, perhaps not so much complicated as requiring significant care in getting everything aligned and perpendicular or at some particular angle or other.

The sticks sticking out the side are plywood and very strong, the are bonded using Epoxy into the center section and bound to the upper and lower main spars, the ribs and the top and bottom sheeting. The ribs themselves are plywood and balsa combined, the center rib being a plywood and balsa sandwich, the balsa being the meat. Very strong. The holes in the top allow for countersunk nylon bolts that will bolt the wing to the fuselage.

The sticks sticking out the side are plywood and very strong, the are bonded using Epoxy into the center section and bound to the upper and lower main spars, the ribs and the top and bottom sheeting. The ribs themselves are plywood and balsa combined, the center rib being a plywood and balsa sandwich, the balsa being the meat. Very strong. The holes in the top allow for countersunk nylon bolts that will bolt the wing to the fuselage.

There were a lot of balsa blocks added to this piece that required a prodigious amount of sanding. As it seemed that this would take an age I hauled out my venerable belt sander and with a medium or so grit belt, inverted it on a workbench, and went at it! It was surprisingly easy as the belt sander runs the belt on a steel flat plate, so the resulting work was completely flat, as long as the angle was correct it was very accurate. Then a hand held finishing sander to round off and finally two block sanders with 80 and 400 grit to make a nice job.

Now to the wings.