Sunday, August 5

Working with these new modern glues is a delightful change from the old stinky crispy stuff. Now, as no doubt all the readers of this will know, one uses Cyanoacrylate Ester, commonly called simply CA Glue. Outside of the hobby it is marketed under various names such as Super-Glue and so on, sold in supermarkets at hugely inflated prices compared to the hobby shop prices. Further to this one can buy it in thin, medium and thick globuleness rates. I found the thin a bit too thin but it has the advantage of creep, or seep; this glue will creep deep into a joint and strengthen it. Anyway, it is very fast and makes building a joy. So at this point we have the fin and tailplane, or stabilizer, or stab - whatever - complete.

Working with these new modern glues is a delightful change from the old stinky crispy stuff. Now, as no doubt all the readers of this will know, one uses Cyanoacrylate Ester, commonly called simply CA Glue. Outside of the hobby it is marketed under various names such as Super-Glue and so on, sold in supermarkets at hugely inflated prices compared to the hobby shop prices. Further to this one can buy it in thin, medium and thick globuleness rates. I found the thin a bit too thin but it has the advantage of creep, or seep; this glue will creep deep into a joint and strengthen it. Anyway, it is very fast and makes building a joy. So at this point we have the fin and tailplane, or stabilizer, or stab - whatever - complete.

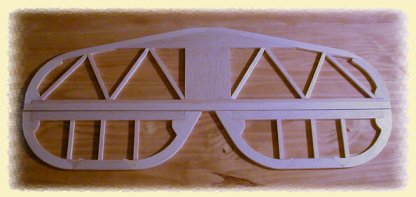

The next step is to add the hinges and fashion hinge angles so the surfaces will flex properly. We will tie the elevators together with a crafty wire bracket and the whole tested without cementing the hinges in place, so we can cover it all you know. Each of the support members has a teeny hole drilled through it laterally so hot air can escape, this air will form when the surface is covered and heat applied.

The next step is to add the hinges and fashion hinge angles so the surfaces will flex properly. We will tie the elevators together with a crafty wire bracket and the whole tested without cementing the hinges in place, so we can cover it all you know. Each of the support members has a teeny hole drilled through it laterally so hot air can escape, this air will form when the surface is covered and heat applied.

Tuesday, August 7

Fitted and installed the hinges on the tailplane and fin. I used a hinge cutting tool for this, two tools in fact. One which slices into the wood at the appointed place and cuts the side of the slot, then a scraping tool that goes in and cleans out the rest of the slot. This all ensures that the slot has height and not just a slit in the wood. Worked very well. Also fitted the tail-wheel hinge and hardware assembly so it would steer with the fin. Finally joined the two elevator halves together with some heavy duty piano wire. This required drilling an 1/8 inch hole into 1/4 inch wood, very little space to spare! But it all worked fine with care and seems solid enough. Finally a grand sanding session to get nice smooth edges.

|